DEFENSE

Mine Blast Attenuating Seat

Design & Evaluation

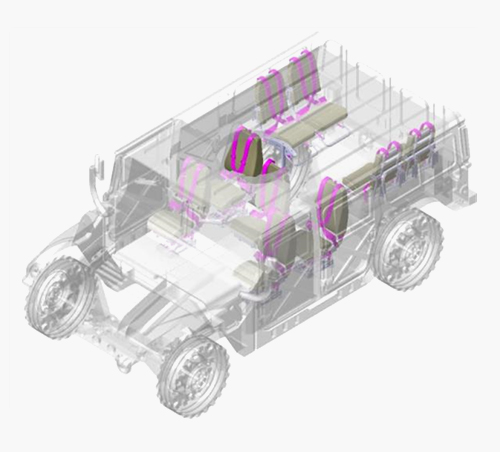

· Provide design solutions suitable for the space of the target vehicle

· Quality assurance based on national defense standards and overseas standards for MINE BLAST ATTENUATING SEAT assembly and component levels

DESIGN SOLUTION(CUSTOM DESIGN)

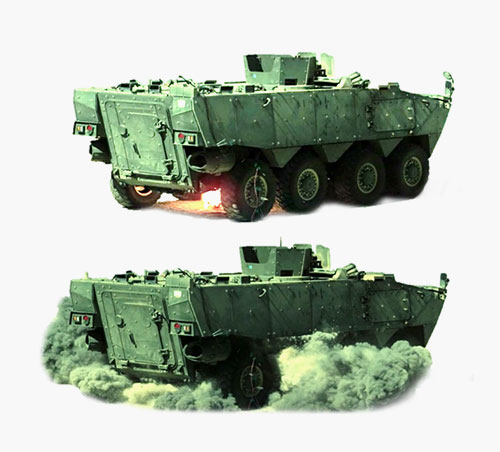

Protect the crew from the effects of landmine and improvised explosive device (IED) blasts

Designed to structurally dissipate the shock of the blast on the vehicle’s body

Damping device (GAS spring) applied, front/rear/up/down height adjustment function

Emergency escape function (driver seat), footrest applied (crew seat)

Variable headrest design (designed according to the use and size of the crew helmet)

T-shaped support, U-shaped support, footrest, and armrest

Custom design according to requirements such as vehicle functions and characteristics (change shape and mounting location, add additional devices, etc.)

Seat belt selection application (4-point or 5-point type)

Provide design solutions suitable for the space of the target vehicle

Prioritize the review of blast attenuation requirements

Considering the severity of blasts for condition 𝒗 and selecting the design according to the requirements

Material selection within the tested range: re-evaluate materials using blast attenuation materials and principles and structural interactions

Selection of energy-absorbing materials that maximize blast energy absorption through elastic and plastic changes

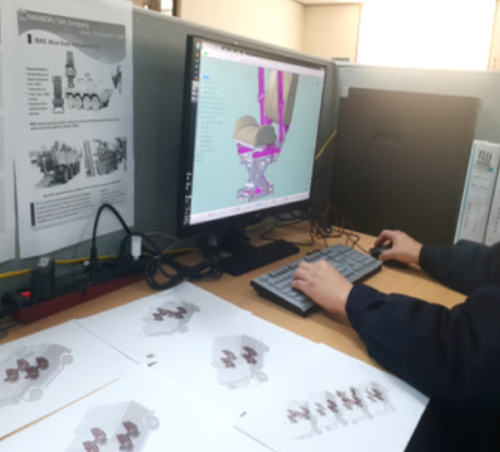

Modeling according to customer requirements

Verification using LS-DYNA blast prediction and analysis software

CAD model design, meshing, and material property verification for real mechanism and model simulation representation

Conducting proven tests at domestic/foreign certified institutions and ensuring quality according to defense/foreign standards

Quality assurance

Drop Test

STANAG 4569 Ed. 2, AEP 55 Vol. Ⅱ

Pull Test

EU Standard ECE No. 14 M3

Vibration Test

MIL- STD- 810G, 514.6